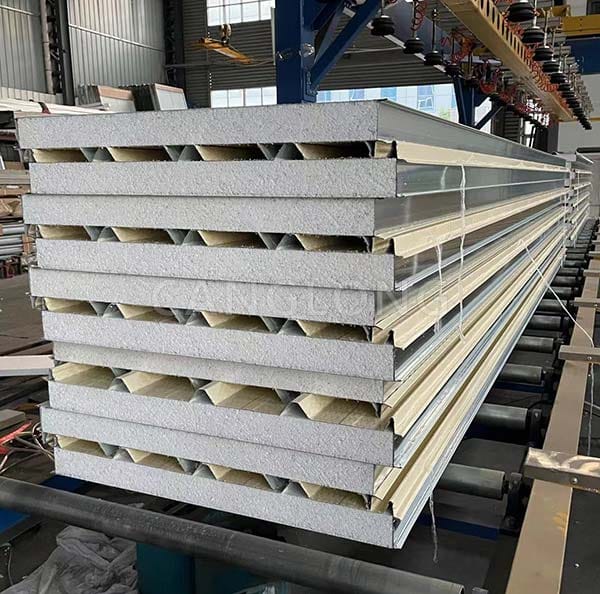

Canglong EPS sandwich panels production process display

EPS sandwich panels have beautiful appearance, good overall effect, bright color, and sound absorption, sound insulation, heat insulation, fire prevention, waterproof and other effects. EPS panels do not require secondary decoration after installation, which reflects the civilized construction of modern construction sites. It can also be disassembled and installed conveniently, effectively reducing the cost of temporary facilities on the construction site. EPS foam sandwich panels are a new type of lightweight building material that is indispensable in modern times.

EPS foam is a very light polymer made of polystyrene resin and foaming agent, which is then heated and softened to produce gas, thereby forming a rigid closed-cell foam. And its processing method can be divided into extrusion method and pattern method according to different foaming methods. It is precisely because of this uniformly closed cavity structure that EPS has the characteristics of low water absorption, good thermal insulation and light weight.

EPS sandwich panels are widely used and are suitable for various warehouses, hospitals, mobile houses and other buildings. Polystyrene foam sandwich panels can be fireproof and fireproof, and are much lighter than other building materials. They are very convenient to install, and the insulation can prevent noise. The foam sandwich panels have strong plasticity.

Features of EPS sandwich panels

1. Light weight, less than 24kg per square meter, which can fully reduce the structural cost.

2. The characteristics of quick installation, light weight, pluggable and free cutting determine the ease of installation, which can improve efficiency and save construction time.

3. Fireproof, the surface material and insulation material of the color steel composite core board are non-combustible or flame retardant materials, which can meet the requirements of fire protection regulations.

4. Fire-resistant, the color steel plate treated with special coating can be kept fresh for 10-15 years, and then sprayed with anti-corrosion coating every ten years, and the service life of the plate can reach more than 35 years.

5. Beautiful, the clear lines of the corrugated steel plate can be as many as dozens of colors, which can meet the needs of any style of architecture.

6. Common insulation materials include rock wool, glass fiber wool, polystyrene, polyurethane, etc. , low thermal conductivity, good insulation effect.

7. Environmental protection and noise prevention. The sound insulation intensity of the composite board can reach 40-50 decibels, which is a very effective sound insulation material.

8. The highly plastic corrugated steel sheet can be cut arbitrarily to meet the needs of special designs.

9. High strength uses high-strength steel sheet as the base material, with a tensile strength of 5600 (kg/cm2), coupled with advanced design and roll forming.

Because EPS sandwich panels are widely used in hospitals, warehouses, venues, etc. For safety reasons, its quality must have certain advantages and meet certain standards. When buying foam sandwich panels, be sure to choose products with good quality from big brands.