Construction precautions for polystyrene sandwich panels

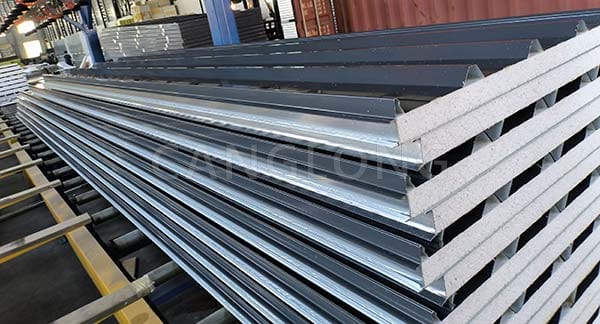

Polystyrene sandwich panels are a commonly used material for thermal insulation of building walls. It is made of two layers of polystyrene board sandwiched with a layer of polystyrene granule foam plastic, and has excellent insulation and heat insulation properties. During the construction process, the following points should be noted:

1. Bottom treatment: Before installing the sandwich panel, it is necessary to treat the bottom wall surface to ensure that it is flat, dry, dust-free, and free of oil stains. It can be treated by brushing or other methods.

2. Fixing method: There are various ways to fix sandwich panels, such as using adhesives, screws, etc. It is necessary to choose a suitable fixing method according to the specific situation, and ensure that the fixing is firm and stable to avoid problems such as hollowing.

3. Construction temperature: The temperature during construction should not be too low or too high, generally requiring construction to be carried out at a temperature of 5 ℃ or above. Too low a temperature can affect the bonding effect of the adhesive, while too high a temperature can cause the adhesive to dry too quickly, making it difficult to stick.

4. Process requirements: The construction of sandwich panels needs to be carried out in accordance with standard requirements, including the size, horizontal verticality, surface smoothness, etc. of the panels. Construction personnel need to be familiar with the construction process requirements of sandwich panels to ensure construction quality.

Polystyrene sandwich panels have the following characteristics in the field of environmentally friendly building materials:

1. Good thermal insulation performance: Polystyrene sandwich panel has a low thermal conductivity, which can effectively isolate heat conduction, improve building insulation performance, and reduce energy consumption.

2. Lightweight: Compared to traditional wall insulation materials, polystyrene sandwich panels have lower density, lighter weight, and are easy to transport and install.

3. Safety and environmental protection: The materials used in polystyrene sandwich panels meet environmental requirements, do not contain harmful substances, and are harmless to human health.

When choosing polystyrene sandwich panels, the following points should be noted:

1. Specification and size: Select appropriate specifications and sizes according to specific construction requirements to ensure that they can meet the needs of the building.

2. Quality certification: Select brands with quality certification to ensure compliance with relevant national standards.

3. After sales service: Choose suppliers with good after-sales service so that problems can be solved in a timely manner during construction.

When installing polystyrene sandwich panels, preparation work before construction is required, including bottom layer treatment, selection of fixing methods, etc. During the construction process, attention should be paid to temperature control and compliance with process requirements to ensure construction quality. After the construction is completed, it is also necessary to protect the materials to avoid external damage.