Do you know the characteristics of sandwich panels?

How is the insulation and sound absorption of sandwich panels?

Many friends will ask us how are the insulation and sound absorption of sandwich panel? I want to use them as materials. Are their insulation and sound absorption effects good? My answer is very affirmative. Absolutely. For those who are new to it, there may be some questions, but I can be very sure that our products can fully meet your needs. Let’s take a look at the specific effects of sandwich panels.

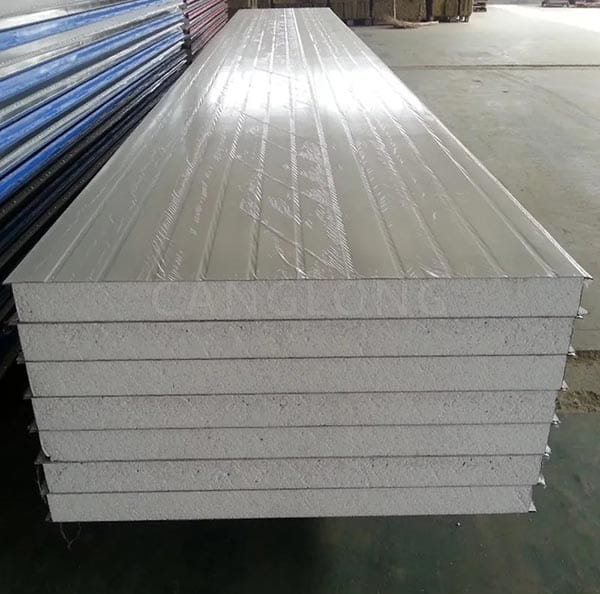

Sandwich panels are composed of two layers of color-coated steel plates as the surface layer, and materials with both rigidity and insulation but relatively low strength, such as rigid foam plastics, rock wool boards and other insulation materials as the core material, which are compounded on an automated production line and have load-bearing structural panels. Due to its structural characteristics, it is also called a “sandwich” board. According to the use of the building and the type of panel, it can be divided into roof panels, wall panels, partition panels and ceiling panels. As a multifunctional new building board, it has the characteristics of heat preservation, sound insulation, strong bearing capacity, bright color, flexible installation, low cost, waterproof and earthquake resistance.

The heat preservation, heat insulation and sound absorption performance of sandwich panels mainly depend on its core material – insulation material. This material must not only have good heat preservation, but also have sufficient strength and rigidity, and have good adhesion with color steel plates. According to the chemical composition of its products, it can be divided into two categories, namely, one is organic chemical foam material, such as polyurethane foam plastic, polystyrene foam plastic, phenolic foam plastic, melamine foam plastic, etc. The other is inorganic fiber material, such as rock wool panel, mineral wool panel, glass wool panel, etc.

Analysis of the waterproof effect of polyurethane edge-sealed sandwich panel

Polyurethane edge-sealed sandwich panels are a kind of board made of natural rocks of good quality such as basalt and gabbro as the main raw materials, which are made of artificial inorganic fibers, slag, and dust content through high-temperature melting and fiberization. It is non-absorbent, especially its waterproofness is more prominent, which is specifically shown in the following points.

- Polyurethane edge-sealed sandwich panel use lightweight polyurethane as the core material of cold storage panels. The advantage of polyurethane is that the waterproof and heat insulation function is very good. The exterior of the polyurethane edge-sealed sandwich panel is composed of color steel plate and stainless steel plate components. The advantage of this is to avoid the temperature transfer caused by the large temperature difference between the inside and outside of the cold storage panel, thereby making the cold storage more energy-saving and improving the working efficiency of the cold storage.

- Polyurethane edge-sealed sandwich panels are fireproof, flame retardant, and high temperature resistant. After adding flame retardants, polyurethane is a flame-retardant self-extinguishing material. Its softening point can reach above 120 degrees Celsius, and it will only decompose at higher temperatures. In addition, polyurethane will form ash on its foam surface when burning, and this layer of ash helps to block the foam below. It can effectively prevent the spread of fire. Moreover, polyurethane does not produce harmful gases at high temperatures.

- Because polyurethane sheets have excellent waterproof and heat-insulating properties, under the same insulation requirements, the thickness of the building’s external protective structure can be reduced, thereby increasing the indoor usable area.