How to choose cold storage panel when building a cold room?

When building a cold room, it is crucial to choose the right cold storage panel. As the main structural material of the cold storage room, the cold storage board is not only related to the thermal insulation performance of the cold room, but also directly affects its service life and operating costs.

Selection Guide for Cold Storage Panels in Cold Room

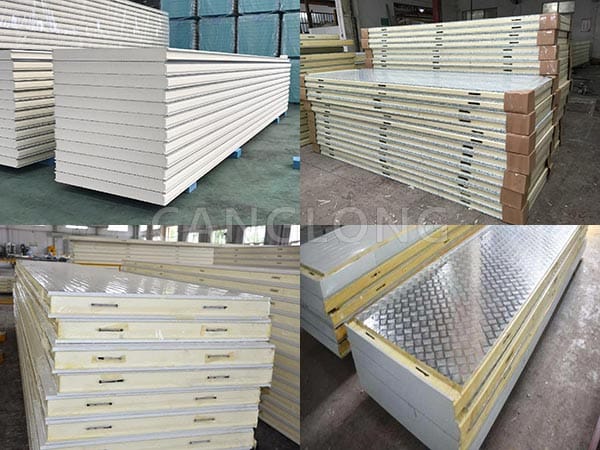

1. Understand the basic types of cold storage panels

There are several common types of cold storage panels on the market, including polystyrene (EPS), polyurethane (PU), extruded polystyrene (XPS) and rock wool cold storage boards.

- Polystyrene cold storage panel: with polystyrene foam as the center, sandwiched between metal materials. It has good thermal insulation performance and light weight, which is convenient for construction. However, its compressive strength is relatively low, and it is suitable for occasions with low load-bearing requirements.

- Polyurethane cold storage panel: with polyurethane foam as the core, covered with galvanized steel plate, etc. Polyurethane cold storage board has excellent thermal insulation performance and high compressive strength, and is suitable for food, electronics and other industries. Although the price is relatively high, its long-term benefits and performance stability make it a high-quality choice.

- Extruded polystyrene cold storage panel: It has excellent thermal insulation and compressive strength, but the price is also high. It is suitable for occasions that require higher thermal insulation and load-bearing capacity.

- Rock wool cold storage board: Made of natural minerals and melted at high temperature. Rock wool cold storage board has the advantages of heat insulation, sound insulation, flame retardancy, etc., and is the preferred material for refrigeration and heat preservation.

2. Consider the specific needs of the cold room

When choosing a cold storage board, the specific needs of the cold room should be fully considered, including the type of stored items, temperature requirements, use environment and climatic conditions.

- Type of stored items: If it is used to store foods such as fruits and vegetables, meat, etc. that require low-temperature refrigeration, you can choose polyurethane or extruded polystyrene cold storage panels with better thermal insulation. These materials can provide better temperature control to ensure the freshness and quality of food.

- Temperature requirements: For cold room that need to control the temperature between -1℃ and -20℃, it is usually necessary to install refrigeration boards with a thickness of 100mm to 140mm. If it is necessary to maintain a temperature below -20℃, such as in laboratories or ultra-fast freezing of meat and fish, the thickness of the refrigeration plate should be between 150mm and 200mm.

- Use environment and climatic conditions: In high temperature and high humidity areas, cold storage plates with good moisture-proof properties, such as polyurethane cold storage plates, should be selected to prevent temperature propagation caused by excessive temperature difference between inside and outside, thereby improving the energy saving effect of the cold storage room.

3. Weighing budget and performance

When choosing cold storage panels, you also need to weigh them according to your own economic ability. If the budget is sufficient, you can give priority to polyurethane or extruded polystyrene cold storage plates with high cost performance. Although these materials are more expensive, they can often reduce the operating costs of cold storage rooms due to their excellent thermal insulation performance and long-term benefits. If the budget is limited, you can choose lower-priced polystyrene cold storage panel and appropriately increase the thickness of the panels to make up for the lack of thermal insulation performance.

4. Choose regular manufacturers and high-quality products

Finally, when choosing cold storage panel, you should make sure to choose products produced by regular manufacturers. Products from regular manufacturers usually have higher quality assurance and more complete after-sales service. At the same time, we should also pay attention to key indicators such as product density, thickness and load-bearing capacity to ensure that the selected products meet the specific needs of the cold room.

In summary, choosing the right cold storage panel is crucial to the performance and life of the cold room. By understanding the characteristics of different materials, considering the specific needs of the cold storage room, weighing budget and performance, and choosing regular manufacturers and high-quality products, we can make more informed decisions, thereby improving the construction efficiency and use effect of the cold room and reducing long-term operating costs.