Tips for judging the quality of PIR sandwich panels

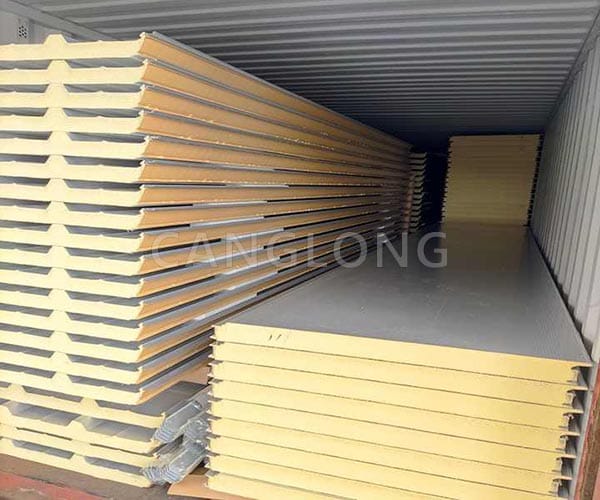

In the field of construction, PIR sandwich panels (polyisocyanurate sandwich panels) are widely used in various construction projects, such as industrial plants, cold storage, mobile houses, etc., due to their excellent thermal insulation, fire retardant, high strength and other properties.

However, the quality of PIR sandwich panels on the market varies, and how to accurately judge their quality has become the focus of attention of consumers and construction practitioners. Mastering some effective judgment skills can not only ensure the quality and safety of construction projects, but also avoid economic losses and safety hazards caused by the use of inferior products.

Appearance inspection is the first step in judging the quality of PIR sandwich panels. The surface of high-quality PIR sandwich panels should be flat and smooth, without obvious defects such as bumps, scratches, bubbles, etc. The coating should be uniform and consistent in color, without sagging or missing coating. For colored PIR sandwich panels, the color should be bright and lasting, and not easy to fade. If there are defects on the surface, it may affect the aesthetics of the sandwich panel. More importantly, these defects may be the external manifestation of internal quality problems, such as unstable process in the production process of the panel, resulting in uneven density of the panel, which in turn affects its overall performance.

Dimensional accuracy is also an important indicator for measuring the quality of PIR sandwich panel. Use a caliper or tape measure to measure the length, width and thickness of the sandwich panel and compare them with the dimensions agreed in the product manual or contract.

Generally speaking, the dimensional deviation of high-quality PIR sandwich panels should be controlled within a small range, with the length and width deviations usually within ±5mm and the thickness deviation within ±0.5mm. Excessive dimensional deviation will not only bring difficulties to installation, resulting in loose splicing, affecting the overall sealing and aesthetics of the building, but may also reduce the structural strength of the sandwich panel and affect its thermal insulation and heat insulation properties.

The quality of the core material is a key factor in determining the performance of PIR sandwich panels. Open the corners of a PIR sandwich panel and observe the texture of the core material. High-quality PIR core materials should present a uniform and fine pore structure, with uniform pore size and uniform distribution, and no obvious large pores or voids. Core materials with tight pore structure have better thermal insulation performance and higher strength. At the same time, the bond between the core material and the panel should be firm, and the core material and the panel should not be separated by hand. If the bond is not firm, the sandwich panel is prone to delamination during use with temperature changes, external forces, etc., resulting in performance degradation.

Fire resistance is one of the important characteristics of PIR sandwich panels and a key indicator for judging their quality. You can understand its fire resistance by checking the product’s fire rating test report. Generally speaking, high-quality PIR sandwich panel should meet the fire resistance standard of B1 or above, that is, flame-retardant building materials, which are difficult to catch fire when exposed to open flames or high temperatures in the air, are not easy to spread quickly, and stop burning immediately when the fire source is removed.

If conditions permit, a simple fire test can also be carried out, such as briefly burning a corner of the sandwich panel with a lighter to observe its burning condition. If the sandwich panel burns quickly when burning and produces a lot of smoke and pungent odor, it means that its fireproof performance is poor and the quality is difficult to guarantee.

Environmental performance should not be ignored either. With the increasing demand for environmental protection, the environmental performance of PIR sandwich panel has also become an important consideration when choosing products. Check the environmental protection test report of the product to understand its formaldehyde emission, volatile organic compound (VOC) content and other indicators. High-quality PIR sandwich panels should meet the relevant national environmental protection standards, have low formaldehyde emission, will not pollute indoor air quality, and protect the health of users.

Judging the quality of PIR sandwich panel require comprehensive consideration from multiple aspects. Through appearance inspection, size measurement, core material observation, fireproof performance testing and environmental performance testing, the quality can be more accurately evaluated.

When purchasing and using PIR sandwich panels, consumers and construction practitioners should choose carefully and strictly control to ensure the quality of the products used, laying a solid foundation for the safety and quality of construction projects. At the same time, strengthening market supervision, cracking down on inferior products and maintaining a good market order are also important measures to promote the healthy development of the PIR sandwich panel industry.