What are the specific specifications and thickness of EPS insulation panel?

As a widely used insulation material, EPS insulation panel has been widely used in wall insulation, roof insulation and other fields due to its advantages such as light weight, good insulation performance and convenient construction. The specific specifications and thickness of EPS insulation board vary according to its application scenarios and needs. This article will introduce the specifications and thickness of EPS insulation sandwich panels in detail and explore its importance in practical applications.

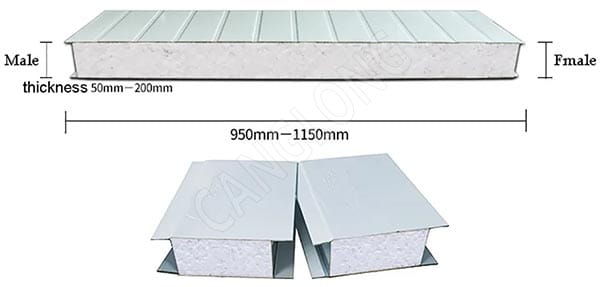

The specifications and dimensions of EPS insulation board mainly include three aspects: board thickness, board length and board width. Generally speaking, the standard specifications of EPS insulation board are 50mm~200mm thick, with common lengths of 2 meters, 2.5 meters or 3 meters, and width is usually 1 meter. However, depending on different application scenarios and specific needs, the specifications and dimensions of EPS insulation board may vary.

In terms of thickness, the thickness unit of EPS insulation board is usually expressed in millimeters (mm), generally between 0.5~600 mm. The specific thickness selection needs to be determined according to the energy-saving requirements of the building, the load it bears, dimensional stability and other performance indicators. For example, in the field of insulation, EPS panels are usually used as a component of the exterior wall insulation system, and their thickness needs to be designed and installed according to the energy-saving requirements of the building. In some high-end applications, the thickness of the EPS insulation panel may reach 200mm or even thicker to meet higher insulation requirements.

In addition to standard specifications, EPS insulation panels can also be customized according to the specific needs of users. Customized EPS insulation sandwich panels will be thicker or thinner than conventional specifications to meet the user’s requirements for insulation effect and use cost. At the same time, according to construction requirements, EPS insulation sandwich panels can also be customized in different lengths and widths to adapt to different wall sizes and shapes.

In terms of board type, EPS insulation boards mainly include flat, spliced and cylindrical types. Flat is the most common EPS insulation panel type, suitable for most building insulation needs. Spliced is a special EPS insulation sandwich panel type that can achieve a larger area of insulation needs through splicing, suitable for large-scale building wall insulation and roof insulation needs. The cylindrical type is suitable for the insulation needs of the cylindrical parts of steel structure buildings. This type of board needs to be customized and made according to specific needs.

The specifications and thickness of EPS sandwich panels have an important impact on their application effect and use cost. On the one hand, reasonable specifications and thickness selection can ensure that the EPS insulation board has good insulation performance and meets the energy-saving requirements of the building. On the other hand, the prices of EPS insulation panels of different specifications and thicknesses will also be different, and users can choose according to their own needs and budget.

In actual applications, the selection of specifications and thickness of EPS insulation boards also needs to consider construction convenience and safety. For example, for scenes such as high-rise buildings or exterior wall tiling, it is necessary to choose EPS insulation panel with higher strength and thicker thickness to ensure safety and stability during construction. At the same time, during transportation and installation, it is also necessary to pay attention to the protection and fixation of EPS sandwich panel to avoid damage or falling off.

In summary, the specifications and thickness of EPS insulation panel vary according to their application scenarios and needs. When choosing EPS insulation boards, users need to make comprehensive considerations based on their own needs and budgets and choose appropriate specifications and thicknesses. At the same time, attention should also be paid to safety and stability issues during the construction process to ensure that the EPS insulation sandwich panel can play its good insulation effect.