What is the clean room sandwich panel?

In high-precision manufacturing fields such as medicine, electronics, and food, clean rooms are key facilities to ensure product quality and safety. As the core building material of cleanrooms, clean room sandwich panel has become the industry’s preferred choice due to their excellent performance. This article will delve into the characteristics, composition, and applications of cleanroom sandwich panels, and recommend the advantages of high-quality sandwich panel supplier – Canglong Group – to help you efficiently build clean spaces.

1. Characteristics of clean room sandwich panel

Cleanroom sandwich panels are designed specifically for high cleanliness environments and have the following core features:

- Dustproof and antibacterial: The surface is smooth and pore free, avoiding dust accumulation, inhibiting bacterial growth, and complying with strict standards such as GMP and ISO.

- Corrosion resistance: Special coating treatment is used to resist the corrosion of chemical reagents and humid environments, extending the service life.

- Thermal insulation and sound insulation: The core material provides efficient thermal insulation and noise reduction, maintaining stable indoor temperature and humidity, and reducing energy consumption.

- High strength and lightweight: The structure is stable and lightweight, making it easy to install quickly and reducing construction costs.

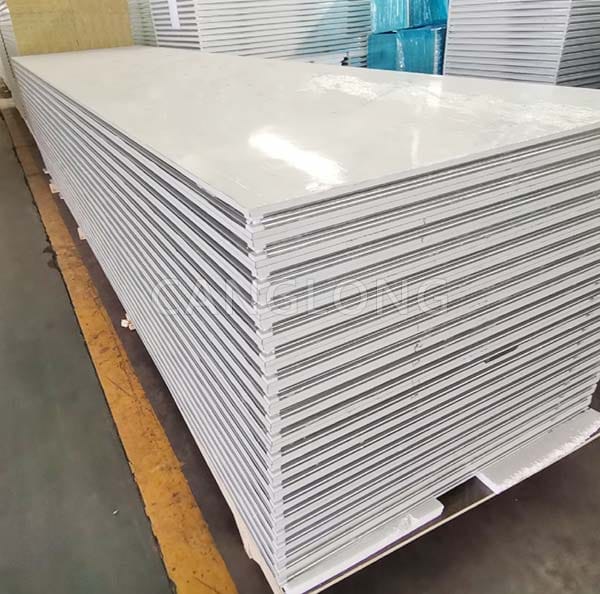

2. Composition of clean room sandwich panel

The clean room panel adopts a “sandwich” structure, consisting of three parts:

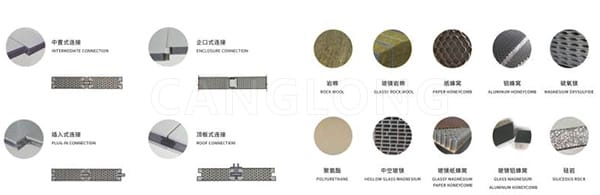

- Surface material: mostly color steel plate, stainless steel or aluminum plate, providing compressive and anti-corrosion protection.

- Core materials: commonly used rock wool, polyurethane (PU), polystyrene (EPS) or aluminum honeycomb, different materials meet diverse needs such as fire prevention and insulation.

- Adhesive: Environmentally friendly adhesive ensures a tight fit between the panel and the core material, without the release of volatile substances, ensuring cleanliness and safety.

3. Application scenarios of cleanroom sandwich panels

Pharmaceutical industry: sterile workshops, laboratories, operating rooms, etc. to ensure zero pollution in drug production.

Electronic manufacturing: chip workshop, precision instrument room, to prevent static electricity and particle interference.

Food processing: Packaging workshop, refrigerated warehouse, in compliance with hygiene standards and temperature control.

Biotechnology: R&D center, clean corridor, ensuring the stability of experimental environment.

4. Advantages of clean room sandwich panel

Compared with traditional building materials, clean room panels have significant advantages:

- Modular design: supports quick assembly and installation, shortening the construction period.

- Convenient maintenance: The surface is easy to clean and disinfect, reducing long-term operation and maintenance costs.

- Environmental protection and energy conservation: Efficient insulation reduces air conditioning load and supports green production.

- Flexible customization: Sizes, colors, and functional layers can be customized according to specific needs.

5. The key to choosing high-quality sandwich panel suppliers

Among numerous sandwich panel suppliers, Canglong Group stands out with the following core advantages:

- Leading technology: Introducing international production lines to produce high-precision clean room sandwich panels, certified by ISO 9001 quality.

- Full product category coverage: providing core materials such as rock wool, PU, glass magnesium, EPS, etc. to meet different cleanliness requirements.

- One stop service: full support from design, production to installation, providing personalized solutions.

- Rich case studies: Serving over a hundred pharmaceutical companies, electronics factories, and laboratories, with guaranteed reputation.

- Worry free after-sales service: global service network, 24-hour response, lifelong maintenance support.

Conclusion

Clean room sandwich panel is the core building materials for building high standard clean environments, and their performance and supplier selection directly affect project quality. As a professional sandwich panel supplier, Canglong Group helps enterprises create safe and efficient clean spaces with technical strength and full process services. Consult Canglong immediately for customized clean room solutions!