What is the difference between building sandwich panels and composite panels?

Building sandwich panels and composite panels are commonly used materials in modern construction. Although they are similar in some aspects, there are significant differences in structure, use and performance. Here are the main differences between the two materials:

1. Definition

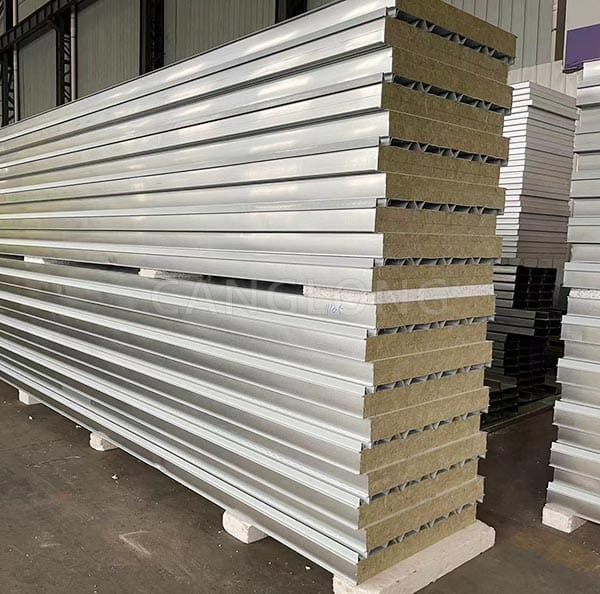

Building Sandwich Panels: Architectural sandwich panels typically consist of two layers of surface material (such as sheet metal, plastic, or other materials) sandwiched between a layer of insulating or lightweight material (such as polystyrene, polyurethane, or rock wool). This structure makes it excellent at thermal, thermal and sound insulation.

Composite panels: Composite panels are panels made from two or more different materials, often used to improve certain properties such as strength, corrosion resistance, or light weight. The core material of the composite panel can be plastic, metal or other materials, and the surface layer can be metal, ceramic, etc.

2. Structure

Sandwich panels: The structural feature of sandwich panels is that the sandwich material plays a load-bearing and thermal insulation role. It is usually used in exterior walls, roofs and interior partitions in construction.

Composite Panels: Composite panels are more diverse in structure and their performance depends on the combination of materials used. Composite panels are mainly designed to improve mechanical performance and durability, and are commonly used in industrial equipment, transportation vehicles, etc.

3. Purpose

Building Sandwich panels: widely used in the construction field, especially in industrial plants, cold storages, warehouses, commercial buildings, etc., mainly used to provide thermal insulation, heat insulation and fire protection properties.

Composite panels: They have a wider range of applications, including aerospace, automobiles, construction, consumer electronics, etc. They are mainly used where lightweight, high strength or corrosion resistance is required.

4. Performance

Sandwich panels: With thermal insulation, heat insulation, sound insulation and light weight as the main performance characteristics, they are suitable for use in building environments that require temperature and noise control.

Composite panels: Mainly emphasizes strength, corrosion resistance, wear resistance, etc., and is suitable for applications that bear large mechanical loads or extreme environments.

5. Cost and Economics

Sandwich panels: usually provide high cost performance in terms of thermal insulation and thermal insulation properties, and are suitable for large-scale construction projects.

Composite Panels: Cost and economics vary depending on material combination, often used in specialty applications requiring high performance.

In conclusion

Building sandwich panels and composite panels each have their own unique advantages and application areas. Selecting the appropriate material depends on the specific needs of the project, including performance requirements, cost budget and application environment. In the construction industry, sandwich panels are widely popular for their excellent insulation properties, while composite panels are used in many other industries for their versatility and high performance.