What is the insulation effect of PIR roof panels?

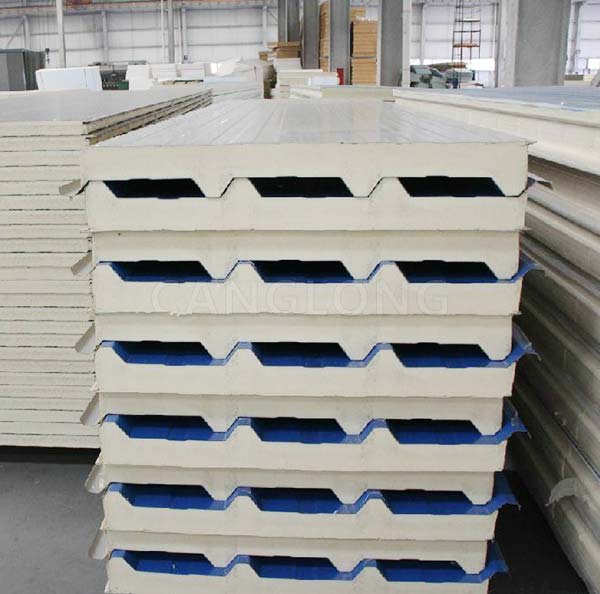

In the construction industry, the choice of insulation materials is critical to the energy efficiency and overall performance of a building. As a rigid foam insulation material, polyisocyanurate (PIR) performs well in the field of roof insulation and has become the first choice for many construction projects. The following is an in-depth look at the thermal insulation effects of PIR roof panels and their advantages in building applications.

PIR roof panels are known for their excellent thermal insulation properties. Its thermal conductivity is extremely low, only 0.018, making it one of the insulation materials with the lowest thermal conductivity at present. This means that PIR roof panel can effectively prevent heat transfer and can perform excellently both for winter insulation and summer insulation. In low-temperature cold storage, the thermal insulation performance of PIR roof panel has been fully verified. It can maintain the low-temperature environment in the cold storage for a long time and reduce energy consumption.

In addition to low thermal conductivity, PIR roof panels have excellent dimensional stability and compressive strength. This allows it to maintain stable insulation performance under various climate conditions and will not deform due to changes in temperature or humidity. At the same time, the high compressive strength ensures that the PIR sandwich roof panels will not deform or be damaged when bearing roof loads, thus ensuring the long-term stability and safety of the building.

The moisture-proof performance of PIR roof panels

is also an important guarantee for its thermal insulation effect. Since the PIR material itself has excellent waterproof properties, the PIR roof panel can effectively prevent moisture penetration and avoid the degradation of thermal insulation performance and building damage caused by moisture. This feature makes PIR roof panels more widely used in humid or rainy areas.

In terms of fire resistance, PIR roof panels also perform well. It has good fire resistance and can maintain structural integrity during fire and slow down the spread of fire. This makes PIR sandwich panel ideal for many construction projects with high fire protection requirements.

PIR roof panels also have the advantages of simple construction, environmental protection and energy saving. It requires less fixings during construction and is compatible with most roofing and wall systems, thereby reducing construction difficulty and cost. At the same time, PIR materials contain recycled components and can be recycled and reused, which is in line with the concept of green building.

In practical applications, PIR sandwich roof panels have been widely used in various building types, including commercial buildings, residential buildings, and industrial buildings. In the field of commercial building roof insulation, the application rate of PIR roof panel exceeds 70%, making it one of the most widely used building products in North America. This is due to its cost-effective insulation solutions and widespread recognition by building codes.

In addition, PIR roof panels have passed a number of authoritative certifications, such as FM Class 1 roofing system certification and UL certification. These certifications prove the excellent performance of PIR panels in terms of thermal insulation performance and fire resistance, and also provide strong support for their wide application in the construction industry.

To sum up, PIR roof panels have become a leader in the field of building insulation due to their excellent thermal insulation properties, excellent dimensional stability and compressive strength, good moisture-proof and fire-proof properties, easy construction, environmental protection and energy saving. In the future construction industry, with the continuous improvement of energy efficiency and environmental protection requirements, the application prospects of PIR roof panel will be broader.