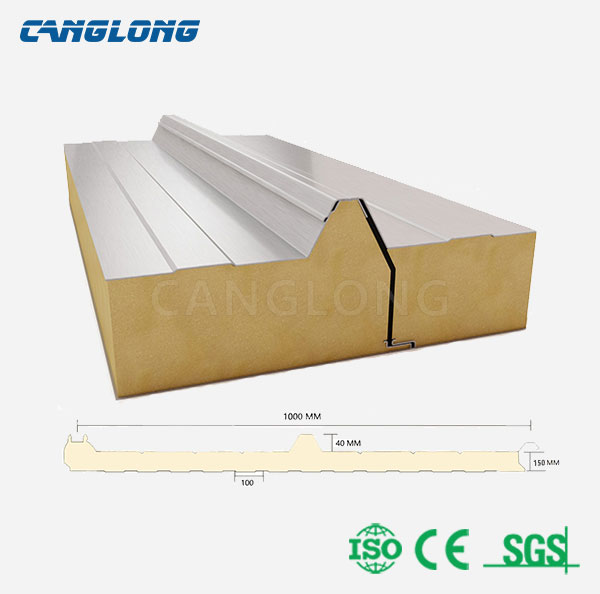

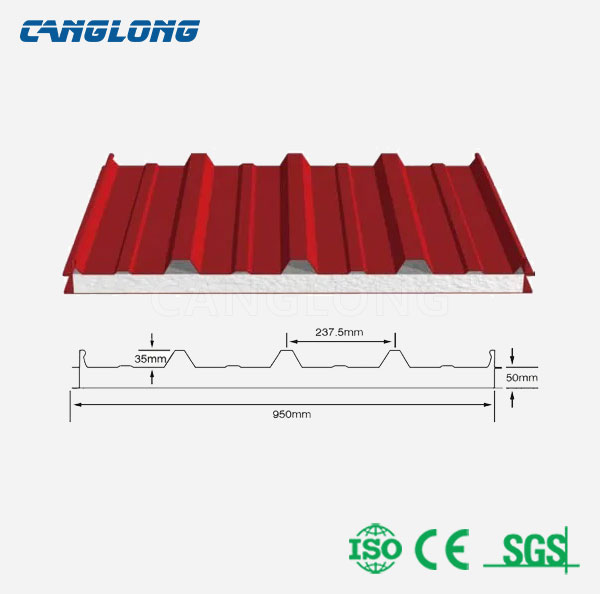

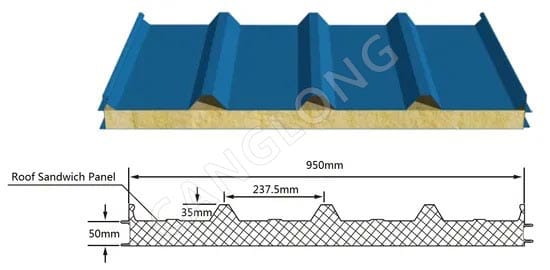

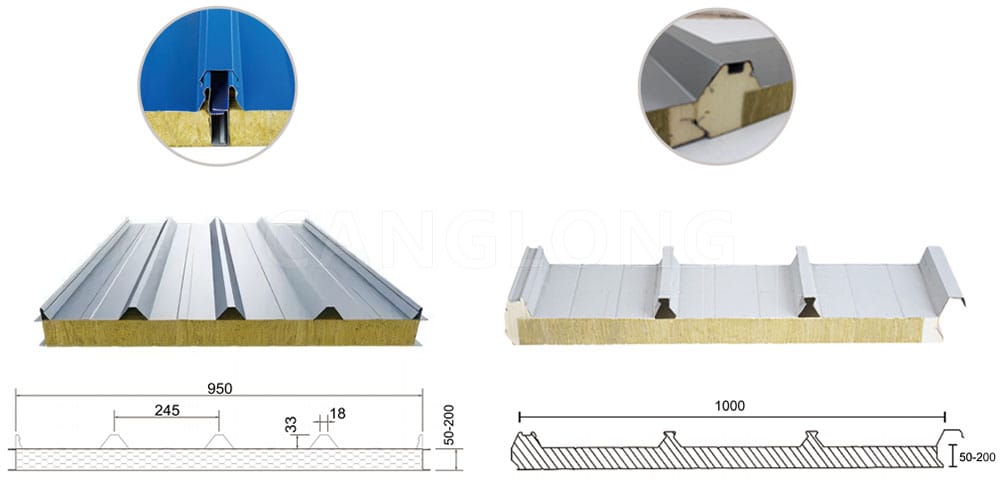

50mm Fire Rated Mineral Wool Roof Panel

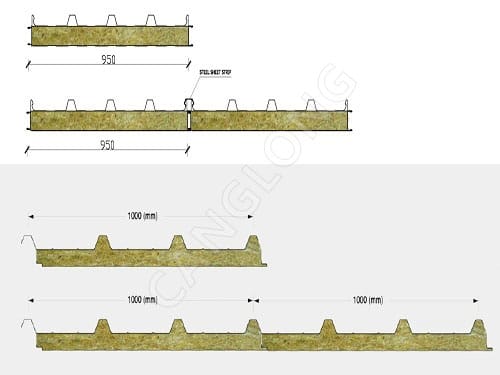

- Effective Width: 950/1000mm

- Core Material Density: 80-120kg/m³

- Metal Sheet Thickness: 0.4mm to 0.8mm

- Color of Steel Plate: White/Offwhite/Blue or Customized

- Core Thickness: 50mm

- Coating: PE/HDP/PVDF/SMF

- Plating: Hot-galvanize/Aluminium/Stainless

- Sound Insulation: ≥30db

- Flammability Rating: A

- Delivery Time: 7-15 days

- Shipping Port: Qingdao Port

- Payment: T/T, L/C, PayPal

- Service Life: ≥15 years

- Product Origin: Henan, China

Product Details

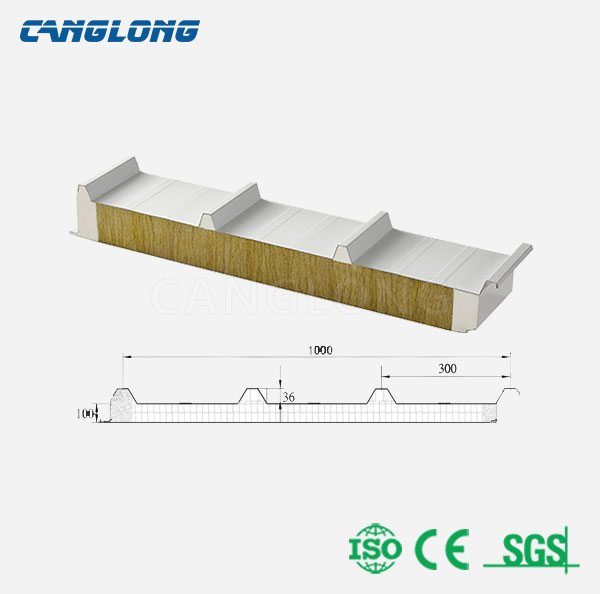

The 50mm thickness fire rated mineral wool roof panel is a specialized building material designed to provide superior thermal insulation and fire resistance for roofing applications. Comprising two outer layers, typically made of metal, and a core of mineral wool insulation, these panels are ideal for industrial, commercial, and residential buildings where fire safety and energy efficiency are paramount.

The 50mm fire-rated mineral wool roof panel is an excellent choice for modern construction, offering a combination of fire safety, thermal insulation, and durability. Its lightweight nature and quick installation process make it suitable for various applications in industrial, commercial, and residential buildings. As fire safety and energy efficiency become increasingly important, these panels stand out as a practical and effective solution for achieving high-performance roofing systems that protect both people and property.

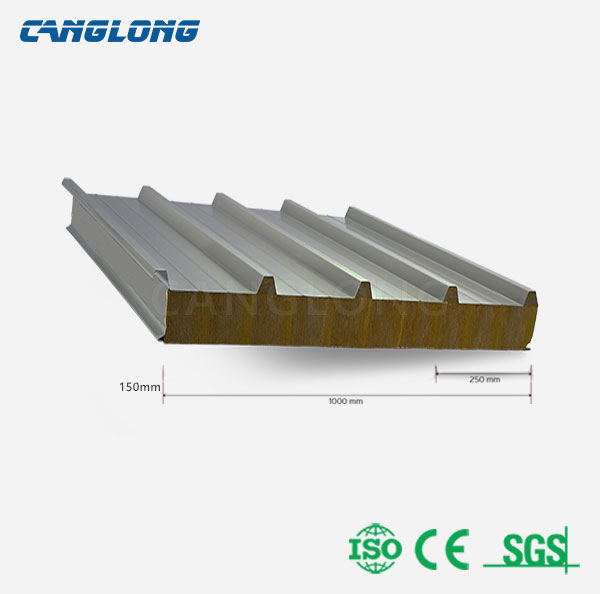

Composition of fire rated mineral wool roof panel

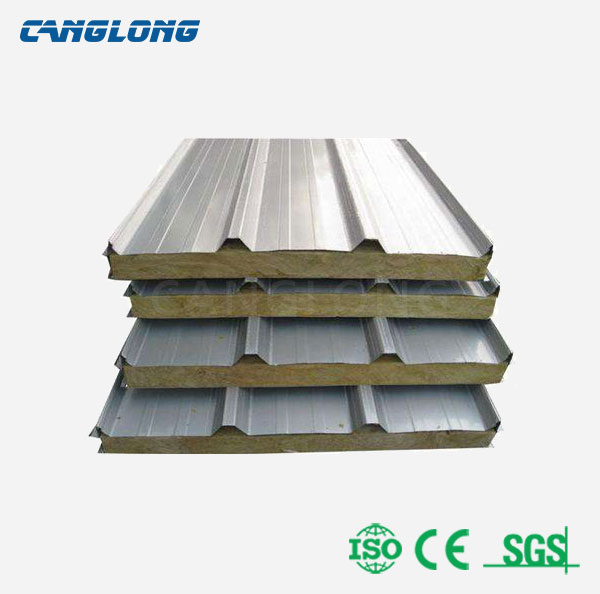

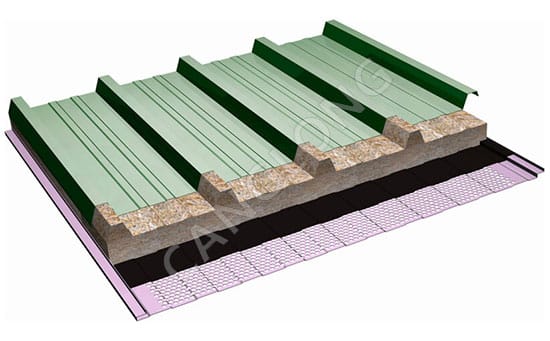

1. Outer Layers: The outer layers are usually constructed from galvanized steel or aluminum, providing durability, corrosion resistance, and protection from environmental elements. These layers can be coated in various finishes to enhance aesthetic appeal and longevity.

2. Core Material: The core is made of mineral wool, an inorganic material that offers excellent thermal insulation and superior fire resistance. It is non-combustible and can withstand high temperatures, making it suitable for applications where fire safety is critical.

Features of fire rated mineral wool roof panel

Fire Resistance: The mineral wool core is classified as non-combustible, significantly enhancing the fire safety of the building. It helps prevent the spread of flames and smoke, providing crucial time for evacuation in the event of a fire.

Thermal Insulation: With a thickness of 50mm, these panels provide excellent insulation, helping to maintain comfortable indoor temperatures and reduce energy costs.

Acoustic Performance: The mineral wool core also offers sound-absorbing properties, reducing noise transmission and improving acoustic comfort within the building.

Durability: The combination of metal outer layers and mineral wool ensures long-lasting performance, with resistance to weathering and mechanical damage.

Rock Wool Sandwich Roof Panel Parameters

| Panel Thickness | Heat Conductivity (W/m2.K) | Weight(kg) | Load capacity (P=KN/M2) | 0.60 | 0.80 | 1.00 | 1.20 | 1.50 |

| 50mm | 0.75 | 15.75 | L(m) | 3.78 | 3.13 | 3.31 | 2.98 | 2.41 |

| 75mm | 0.53 | 18.68 | L(m) | 4.83 | 4.21 | 4.21 | 3.76 | 3.01 |

| 100mm | 0.41 | 21.62 | L(m) | 5.77 | 5.02 | 5.02 | 4.47 | 3.55 |

| 150mm | 0.31 | 27.51 | L(m) | 7.53 | 6.54 | 6.54 | 5.82 | 4.61 |

Applications of 50mm fire rated mineral wool roof panel

50mm thickness fire-rated mineral wool roof panels are suitable for various applications, including:

- Industrial Buildings: Used in factories, warehouses, and manufacturing plants where fire safety and thermal insulation are essential.

- Commercial Structures: Ideal for shopping centers, office buildings, and schools, contributing to energy efficiency and safety.

- Cold Storage Facilities: Suitable for refrigerated warehouses and food processing areas, where maintaining low temperatures is critical while ensuring fire safety.

- Residential Roofs: Increasingly used in modern homes, providing energy savings and peace of mind regarding fire safety.

Advantages of fire rated mineral wool roof panel

Energy Efficiency: The excellent insulation properties help reduce heating and cooling costs, contributing to lower energy bills and a smaller carbon footprint.

Quick Installation: Prefabricated panels allow for rapid installation, which can significantly reduce labor costs and construction time.

Sustainability: Mineral wool is made from natural and recycled materials, and many manufacturers focus on sustainable production practices.

Versatile Design: Available in various finishes and can be customized to meet specific architectural requirements.

Installation of mineral wool roof panel

The installation of 50mm fire-rated mineral wool roof panels involves:

- Preparation: Ensure that the roof structure is clean, dry, and structurally sound.

- Panel Placement: Align and secure the panels to the roof structure using appropriate fasteners, ensuring tight seams to prevent air and moisture infiltration.

- Sealing: Apply sealants at joints and edges to enhance insulation performance and prevent leaks.

Sandwich Panel Production Workshop

Sandwich Panel Packing & Shipping

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

Packing: Per customer's requirements or per product sizes, full protection packing.

Shipping: Per customer's requirements or per container sizes.

Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.

Our Certificates

Our sandwich panel certificates include EU CE certification, BPS certification, and ICC certification.

Application of Sandwich Panels

Usage scenario: Insulated sandwich panels are used as exterior walls and interior partitions, installed vertically or horizontally on single span or multi span structures. Such as industrial buildings, steel frame structures, warehouses and logistics centers, commercial buildings and offices, fire-resistant buildings, agricultural and livestock buildings, sports halls, exhibition halls, factories, garages, hangars, barns, prefabricated houses, cold storage, clean room, etc.

We provide the following RAL color card colors for your reference. For other colors, please compare the Raul color card colors.

Note: The above color card has a slight deviation due to printing reasons, please refer to the actual products.

If you purchase metal sandwich panels from Canglong Group, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

High-quality Raw Materials

We strictly select high-quality suppliers. All color steel coils and core materials are from China top 500 companies and have undergone strict quality inspections to ensure the basic quality of the products.

-

Advanced Production Equipment

The factory is equipped with advanced production equipment, including automated production lines, cNc cutting machines and high-precision pressing equipment, to ensure that the production process of each color steel sandwich panel is accurate and stable.

-

Mature Supply Solutions

One-stop supply of all accessories for sandwich panel installation, standardized packaging process, to avoid friction or damage of sandwich panels on the road, easy for customers to unload, saving time and money for customers.

-

Q1: What are the main applications of polyurethane sandwich panels?

A: Polyurethane sandwich panels are commonly used for insulation and construction in various building types, including residential, commercial, industrial, and agricultural structures. They are suitable for walls, roofs, ceilings, and floors.

Q2: What are the advantages of polyurethane sandwich panels?

A: Polyurethane sandwich panels offer excellent thermal insulation properties, lightweight construction, high strength-to-weight ratio, versatility, weather resistance, fire resistance (with appropriate treatments), aesthetic appeal, and cost-effectiveness.

Q3: How do polyurethane sandwich panels contribute to energy efficiency?

A: Polyurethane sandwich panels provide effective thermal insulation, reducing heat transfer through walls and roofs. This helps maintain comfortable indoor temperatures and reduces the energy required for heating and cooling, thus contributing to energy efficiency and lower utility bills.

Q4: Are polyurethane sandwich panels environmentally friendly?

A: Polyurethane sandwich panels can be environmentally friendly when produced using sustainable manufacturing practices and materials. Additionally, their energy-saving properties contribute to overall environmental sustainability by reducing energy consumption and greenhouse gas emissions.

Q5: How durable are polyurethane sandwich panels?

A: Polyurethane sandwich panels are known for their durability and resistance to various environmental factors, including weather, moisture, and corrosion. Proper installation and maintenance can further enhance their longevity.

Q6: Are polyurethane sandwich panels easy to install?

A: Yes, polyurethane sandwich panels are relatively easy to install compared to traditional building materials. Their lightweight nature and standardized dimensions facilitate quick and efficient installation, resulting in reduced construction time and labor costs.

Q7: Can polyurethane sandwich panels be customized?

A: Yes, polyurethane sandwich panels can be customized to meet specific design requirements, including color, finish, thickness, and profile. Customization options allow architects and builders to achieve desired aesthetics and performance characteristics for their projects.

Q8: How do I maintain polyurethane sandwich panels?

A: Maintenance requirements for polyurethane sandwich panels are minimal. Regular cleaning with mild detergent and water, inspection for any damage or deterioration, and prompt repair of any issues are recommended to ensure optimal performance and longevity.

Product Features

The metal sandwich panels produced by Canglong are insulated, fire-resistant, environmentally friendly, earthquake resistant, and durable.