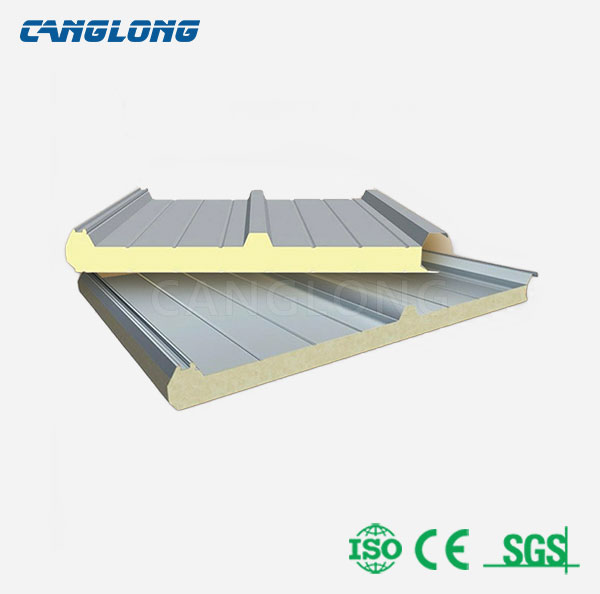

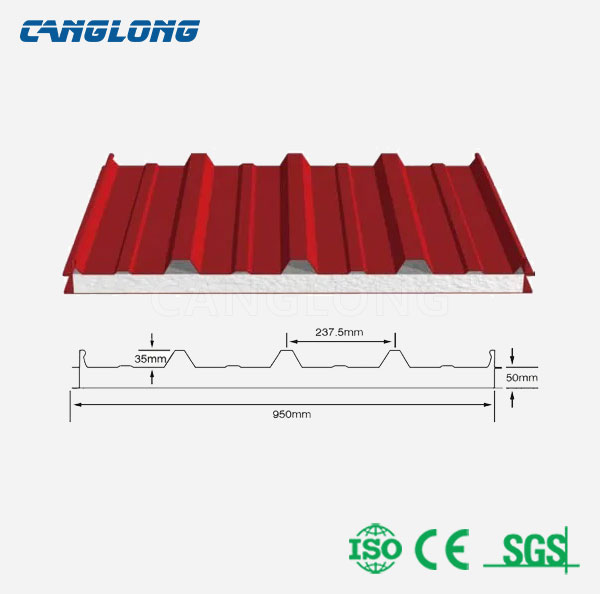

50mm Thick EPS Roof Panel

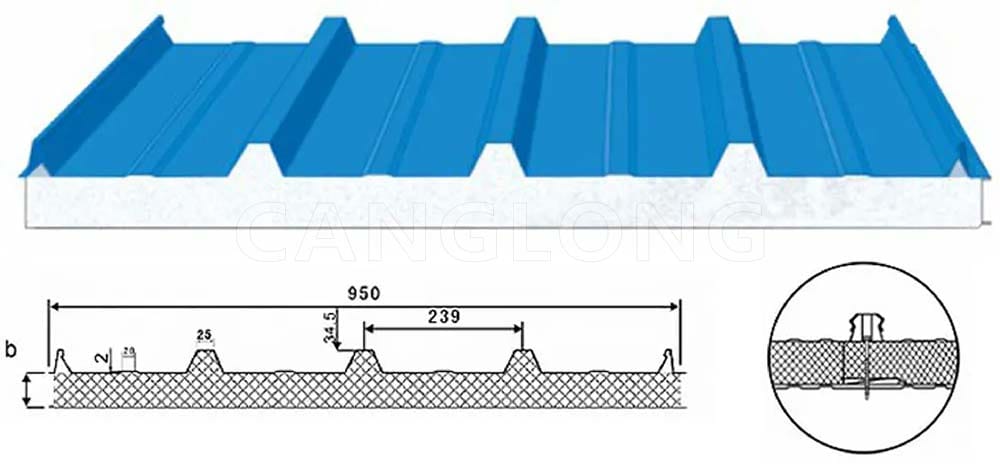

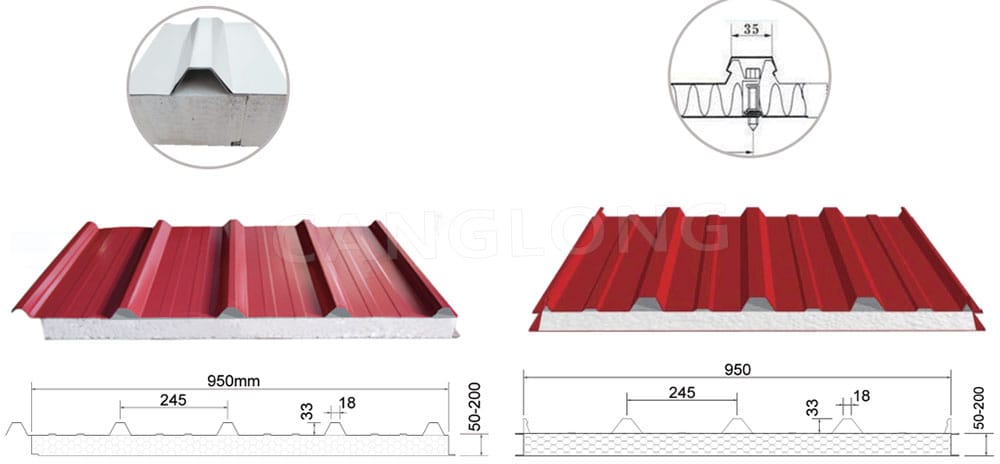

- Effective Width: 950mm

- Metal Sheet Thickness: 0.2mm to 0.8mm

- Coating and Plating: PE/HDP/PVDF/SMF/Hot-galvanize/Aluminium/Stainless

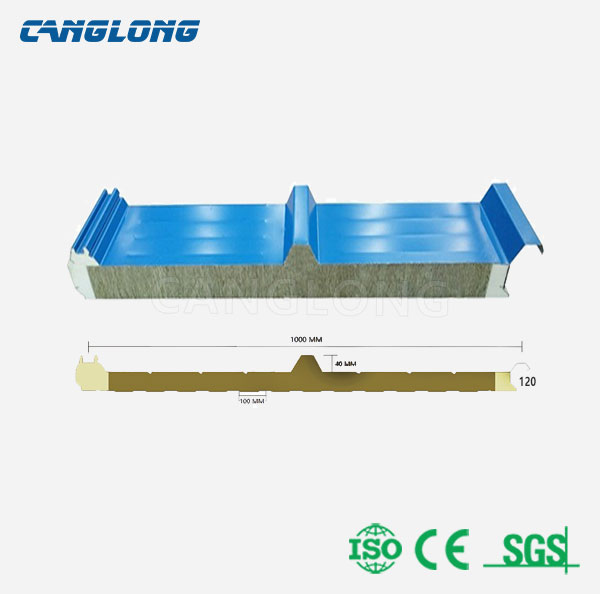

- Color of Steel Plate: White/Offwhite/Blue or Customized

- Core Material: Polystyrene (EPS)

- Core Thickness: 50mm

- Delivery Time: 7-15 days

- Shipping Port: Qingdao Port

- Payment: T/T, L/C, PayPal

- Service Life: ≥15 years

- Product Origin: Henan, China

Product Details

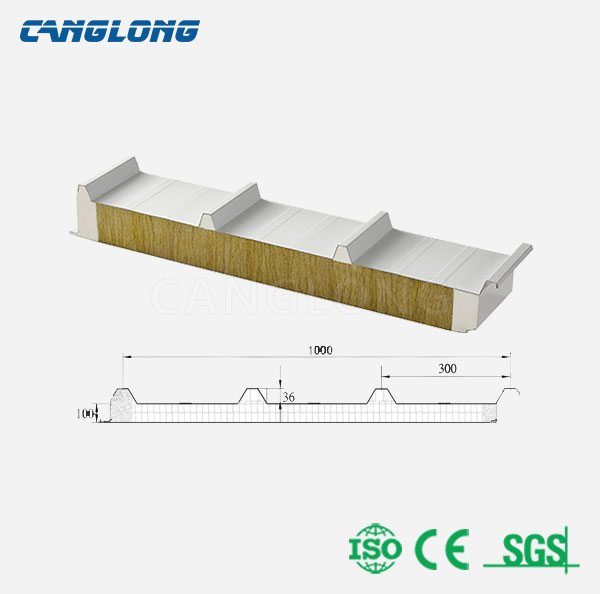

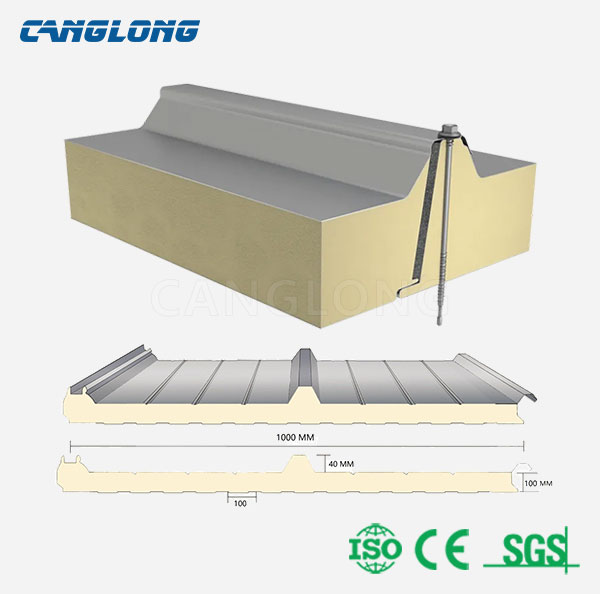

EPS roof panel is mainly made of polystyrene particles through foaming molding, and the interior is filled with countless tiny closed pores. These pores give the EPS panel unique thermal insulation properties. At the same time, the 50mm thickness design not only ensures sufficient thermal insulation effect, but also reduces the weight of the roof.

Characteristics of 50mm thick EPS roof panel

- Excellent thermal insulation performance: The closed-cell structure inside the EPS roof sandwich panel can effectively prevent the transfer of heat. Whether it is winter insulation or summer insulation, it can provide a stable temperature environment for the room and reduce energy consumption.

- Light weight and high strength: The density of the EPS roof board is relatively low, which is easy to carry and install. At the same time, it has certain compressive strength and bending strength, and can withstand certain external forces without being easily damaged.

- Good waterproof performance: Although the EPS roof panel itself is not a completely waterproof material, due to its closed-cell structure, it can effectively prevent the penetration of moisture and keep the roof dry.

- Strong weather resistance: EPS sandwich roof panels have high weather resistance, can adapt to different climatic conditions, and maintain the overall stability and thermal insulation effect of the system.

- Good processing performance: EPS roof panels can be cut, spliced and processed according to different building requirements, and can adapt to various complex roof shapes and structures.

EPS Sandwich Roof Panel – Span Table

| Thickness (mm) | Single span(mm) | Multi-span(mm) | ||||||||||||

| 1500 | 2700 | 3900 | 5100 | 6300 | 7500 | 8700 | 1500 | 2700 | 3900 | 5100 | 6300 | 7500 | 8700 | |

| 50 | 5.16 | 2.35 | 1.28 | – | – | – | – | 4.15 | 2.07 | 1.17 | – | – | – | – |

| 75 | 7.70 | 3.74 | 2.00 | 1.21 | – | – | – | 5.9 | 2.91 | 1.72 | 1.11 | – | – | – |

| 100 | 9.41 | 4.63 | 2.55 | 1.53 | 1.04 | 0.76 | – | 7.61 | 4 | 2.41 | 1.58 | 1.1 | – | – |

| 125 | 10.98 | 5.55 | 3.11 | 1.86 | 1.25 | 0.92 | – | 7.74 | 4.25 | 2.95 | 1.98 | 1.4 | 1.03 | – |

| 150 | 13.26 | 6.78 | 3.67 | 2.19 | 1.47 | 1.07 | 0.82 | 7.74 | 4.35 | 3.04 | 2.35 | 1.77 | 1.31 | – |

Application of 50mm thick EPS roof panels

EPS roof panels are widely used in roof insulation projects of various buildings, such as residential, commercial buildings, industrial plants, etc. Especially in areas where good thermal insulation effects are required, EPS roof panels have become the preferred material.

Advantages of 50mm thick EPS roof panels

- Energy saving and environmental protection: EPS roof panels have excellent thermal insulation performance, which can greatly reduce the energy consumption of heating and air-conditioning equipment, and comply with national energy conservation and emission reduction policies.

- Reduce costs: The production cost of EPS roof panel is low and the market supply is sufficient, which makes it have a high cost-effectiveness in construction projects and can meet the needs of projects of different sizes and budgets.

- Simple construction: EPS sandwich roof panels are light in weight, easy to carry and install, which greatly shortens the construction period and reduces labor costs and time costs.

- Extended service life: EPS roof panels have good weather resistance and corrosion resistance, can resist the erosion of chemicals such as acids and alkalis, extend service life and reduce maintenance costs.

Sandwich Panel Production Workshop

Sandwich Panel Packing & Shipping

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged. And all the structure components, panels, bolts and sorts of accessories will be well packed with standard package and it is suitable for ocean transport.

Inspection: 50% inline inspection and 100% full final inspection, make sure all output w/o any mistake.

Packing: Per customer's requirements or per product sizes, full protection packing.

Shipping: Per customer's requirements or per container sizes.

Unloading: We package it as a whole and can be easily pulled out at once with a forklift, which is very convenient.

Our Certificates

Our sandwich panel certificates include EU CE certification, BPS certification, and ICC certification.

Application of Sandwich Panels

Usage scenario: Insulated sandwich panels are used as exterior walls and interior partitions, installed vertically or horizontally on single span or multi span structures. Such as industrial buildings, steel frame structures, warehouses and logistics centers, commercial buildings and offices, fire-resistant buildings, agricultural and livestock buildings, sports halls, exhibition halls, factories, garages, hangars, barns, prefabricated houses, cold storage, clean room, etc.

We provide the following RAL color card colors for your reference. For other colors, please compare the Raul color card colors.

Note: The above color card has a slight deviation due to printing reasons, please refer to the actual products.

If you purchase metal sandwich panels from Canglong Group, we will also provide some accessory products, including self tapping nails, rivets, waterproof caps, polyurethane glass glue, mouth and corner accessories, outer ridge tiles, waterproof eaves, external and internal corners, eaves edging, plugs, door and window edging, purified aluminum profiles, etc.

High-quality Raw Materials

We strictly select high-quality suppliers. All color steel coils and core materials are from China top 500 companies and have undergone strict quality inspections to ensure the basic quality of the products.

-

Advanced Production Equipment

The factory is equipped with advanced production equipment, including automated production lines, cNc cutting machines and high-precision pressing equipment, to ensure that the production process of each color steel sandwich panel is accurate and stable.

-

Mature Supply Solutions

One-stop supply of all accessories for sandwich panel installation, standardized packaging process, to avoid friction or damage of sandwich panels on the road, easy for customers to unload, saving time and money for customers.

-

Q1: What are the main applications of polyurethane sandwich panels?

A: Polyurethane sandwich panels are commonly used for insulation and construction in various building types, including residential, commercial, industrial, and agricultural structures. They are suitable for walls, roofs, ceilings, and floors.

Q2: What are the advantages of polyurethane sandwich panels?

A: Polyurethane sandwich panels offer excellent thermal insulation properties, lightweight construction, high strength-to-weight ratio, versatility, weather resistance, fire resistance (with appropriate treatments), aesthetic appeal, and cost-effectiveness.

Q3: How do polyurethane sandwich panels contribute to energy efficiency?

A: Polyurethane sandwich panels provide effective thermal insulation, reducing heat transfer through walls and roofs. This helps maintain comfortable indoor temperatures and reduces the energy required for heating and cooling, thus contributing to energy efficiency and lower utility bills.

Q4: Are polyurethane sandwich panels environmentally friendly?

A: Polyurethane sandwich panels can be environmentally friendly when produced using sustainable manufacturing practices and materials. Additionally, their energy-saving properties contribute to overall environmental sustainability by reducing energy consumption and greenhouse gas emissions.

Q5: How durable are polyurethane sandwich panels?

A: Polyurethane sandwich panels are known for their durability and resistance to various environmental factors, including weather, moisture, and corrosion. Proper installation and maintenance can further enhance their longevity.

Q6: Are polyurethane sandwich panels easy to install?

A: Yes, polyurethane sandwich panels are relatively easy to install compared to traditional building materials. Their lightweight nature and standardized dimensions facilitate quick and efficient installation, resulting in reduced construction time and labor costs.

Q7: Can polyurethane sandwich panels be customized?

A: Yes, polyurethane sandwich panels can be customized to meet specific design requirements, including color, finish, thickness, and profile. Customization options allow architects and builders to achieve desired aesthetics and performance characteristics for their projects.

Q8: How do I maintain polyurethane sandwich panels?

A: Maintenance requirements for polyurethane sandwich panels are minimal. Regular cleaning with mild detergent and water, inspection for any damage or deterioration, and prompt repair of any issues are recommended to ensure optimal performance and longevity.

Product Features

The metal sandwich panels produced by Canglong are insulated, fire-resistant, environmentally friendly, earthquake resistant, and durable.