Large Daily Output

Delivery Time: 2025-3-17

Project Name: warehouse

Two containers of PU wall panels shipped to Chile

As a professional supplier of building materials, Canglong Group recently provided customized steel structure and PU sandwich panel solutions for Chilean customers’ warehouse projects. At present, the first batch of 2 containers with a total of more than 2,400 square meters of PU wall panels have been successfully shipped to South America, marking the substantive implementation of the cooperation between the two parties. The project has built a functional and economical storage space for customers through the combination of innovative technology and material performance.

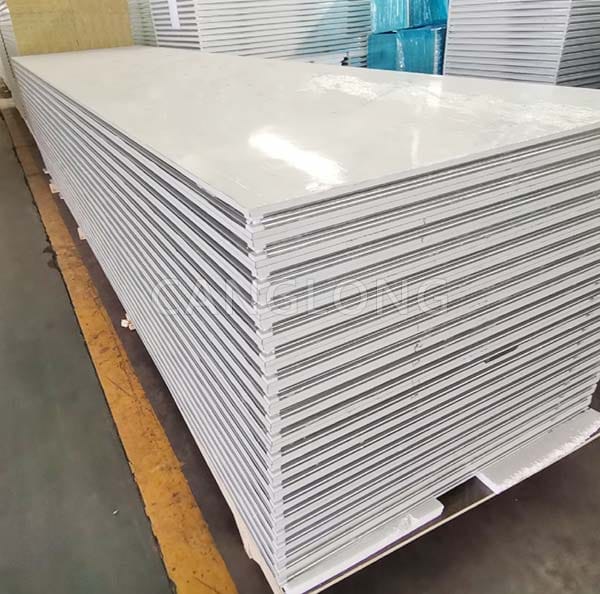

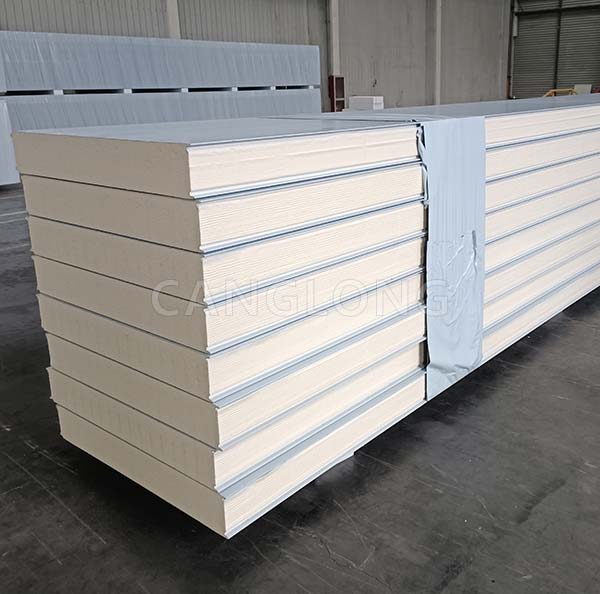

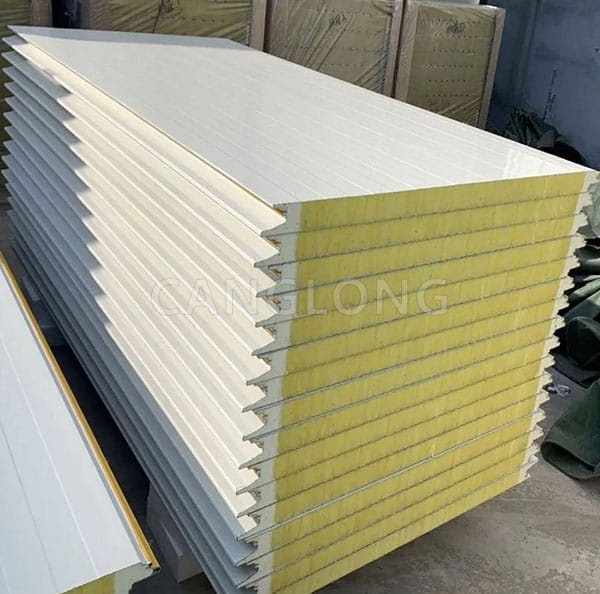

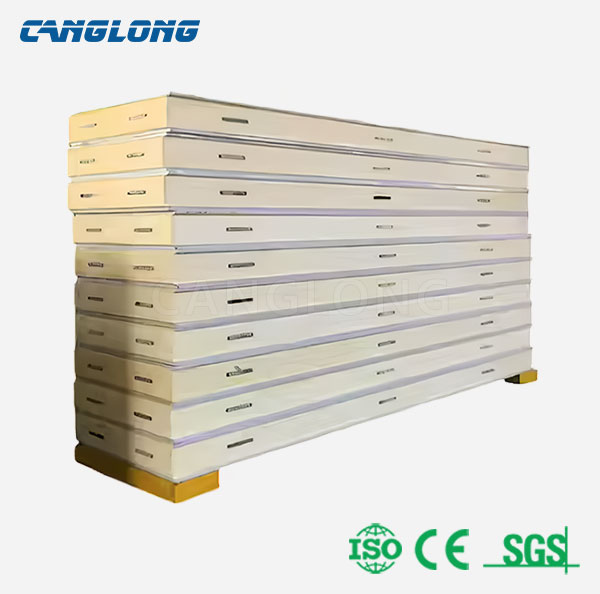

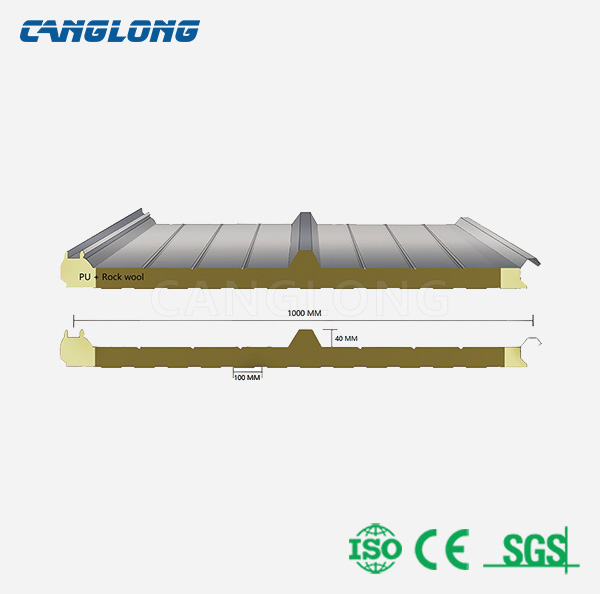

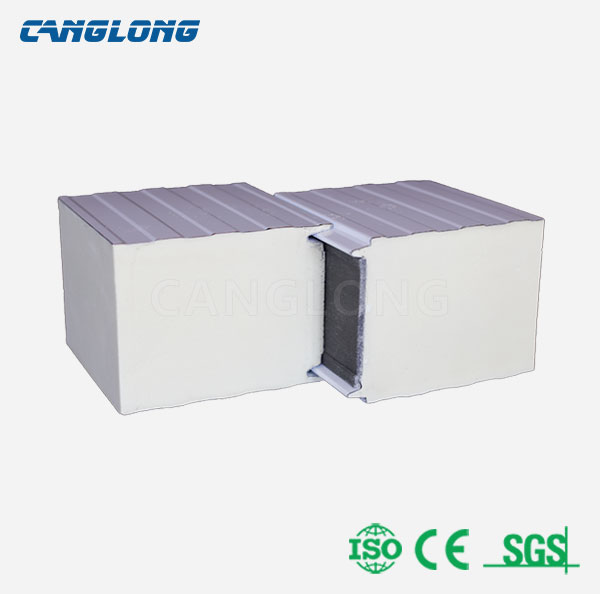

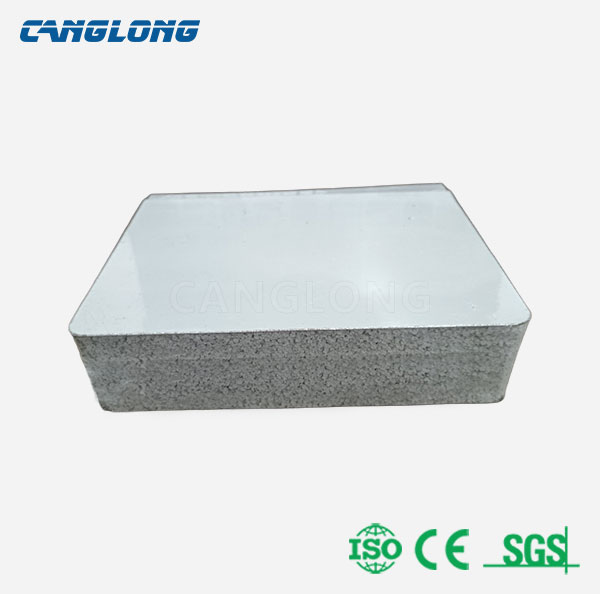

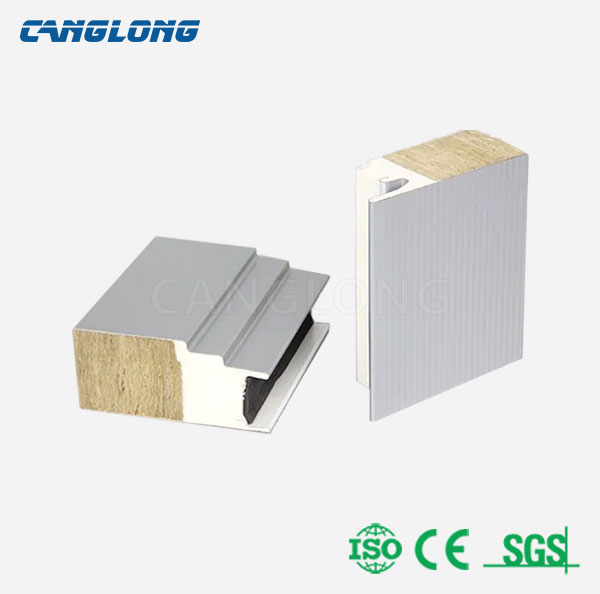

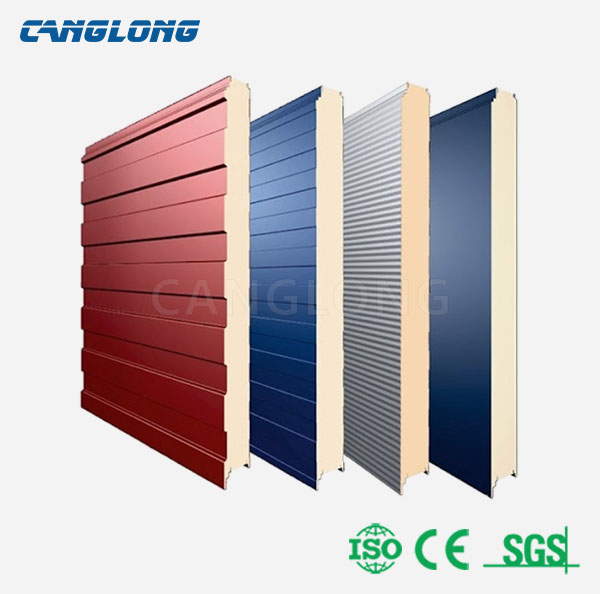

Canglong Group’s PU wall panels are manufactured using advanced continuous production lines. Through the automated polyurethane foaming process, high-strength color steel plates are tightly bonded to closed-cell polyurethane core materials. This structure enables the panels to have excellent thermal insulation properties (thermal conductivity ≤ 0.024W/(m・K)), while also having fire resistance (B1 flame retardant), moisture resistance, and sound insulation. The edge of the board adopts a double dovetail groove design, combined with cold bridge-free connectors to ensure tight joints after installation and effectively avoid heat loss.

In view of the local climate characteristics of Chile, which has a large temperature difference between day and night and high humidity, Canglong Group customized 50mm thick PU wall panels for customers to ensure stable temperature and humidity inside the warehouse and guarantee the quality of cargo storage. In addition, the fluorocarbon coating on the surface of the board can resist sea breeze corrosion and extend the life of the building. Customer feedback shows that this solution not only meets the storage needs, but also reduces the subsequent operating costs through energy-saving design, and it is expected that the annual energy consumption cost will be saved by about 25%.

In the field of warehousing, the application of PU sandwich panels brings multiple values to customers:

- Fast construction: Standardized boards can be prefabricated and assembled on site in modularized manner. Compared with traditional brick-concrete structures, the construction period is shortened by more than 40%, helping customers seize the market opportunity.

- Full life cycle cost optimization: The stability of the polyurethane core material enables it to perform long-lastingly in an environment of -50℃ to 120℃, and the maintenance cost is reduced by 60%. The plate has a light weight (about 15kg/㎡), which reduces the foundation load-bearing requirements and further saves construction costs.

- Improved space utilization: The plate thickness only needs to be 50-200mm, which can release more than 10% of the storage area compared to traditional walls. With the large-span steel structure, flexible space separation and efficient utilization can be achieved.

Choose Canglong for the best service

Our Shipment

Canglong sandwich panel manufacturer has a complete delivery system, and everything from production completion to packaging and loading will be carried out strictly in accordance with regulations.

Good Raw Materials

Fast Production

Overall Packaging

Fast Delivery

Convenient Unloading

Damage Compensation

Feel free to get in touch

Learn more about this project?