Comparison between PUR sandwich panels and PIR sandwich panels

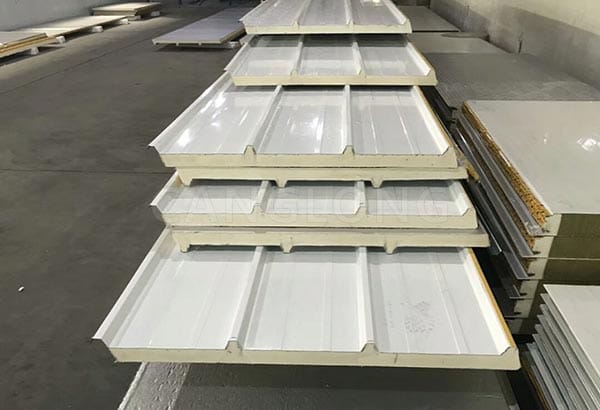

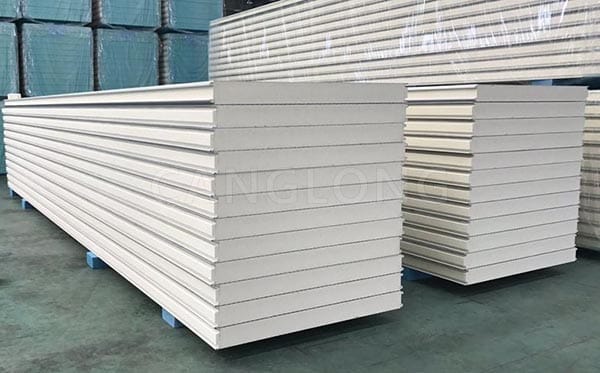

In modern buildings, sandwich panels are widely used due to their excellent thermal insulation properties and lightweight properties. PUR (polyurethane) sandwich panels and PIR (polyisocyanurate) sandwich panels are two common sandwich materials. Although they are similar in appearance and use, there are significant differences in chemical composition, performance and applicable scenarios. This article will conduct a detailed comparison between PUR sandwich panels and PIR sandwich panels and analyze them from the aspects of material properties, thermal performance, fire performance, application fields and cost to help choose the appropriate building materials.

1. Material properties

PUR sandwich panel

The core material of PUR sandwich panel is polyurethane, which has excellent thermal insulation properties. The density of PUR is usually between 30-40 kg/m³, which is lightweight and easy to process. Its excellent thermal insulation performance makes PUR sandwich panels widely used in construction, especially in situations where good thermal insulation effect is required.

PIR sandwich panel

The core material of PIR sandwich panels is polyisocyanurate, which is an improved version of polyurethane. Although PIR has a similar structure to PUR, due to its different chemical composition, PIR generally has higher thermal stability and better fire resistance. The density of PIR is slightly higher than that of PUR, usually between 40-50 kg/m³.

2. Thermal performance

Thermal conductivity

The thermal conductivity of PUR sandwich panel is usually between 0.020-0.025 W/m·K, providing good thermal insulation effect. PUR’s excellent thermal insulation properties enable buildings to effectively save energy and reduce energy consumption in air conditioning and heating systems.

In comparison, the thermal conductivity of PIR sandwich panel is slightly lower, usually between 0.020-0.023 W/m·K. This allows PIR to provide better thermal insulation effect at the same thickness, especially suitable for buildings with higher energy efficiency requirements.

Expansion coefficient

The expansion coefficients of PUR and PIR are similar, but PIR has stronger dimensional stability in high temperature environments. This means that under extreme climatic conditions, PIR sandwich panels will deform and shrink less, thus maintaining their structural integrity.

3. Fire resistance

Fire rating

PUR sandwich panels have relatively low fire resistance and are generally classified as Class B2 (combustible material). Under fire conditions, PUR releases toxic smoke and burns quickly. Therefore, PUR may not be the best choice in buildings requiring strict fire protection requirements.

PIR sandwich panels perform better in fire resistance and are usually classified as Class B1 (flammable material). PIR produces less smoke when burning and has stronger self-extinguishing properties, which can effectively reduce the risk of fire. This makes PIR more suitable for use in industrial buildings, public facilities and other occasions with high fire protection requirements.

4. Application areas

Application of PUR sandwich panel

Due to its excellent thermal insulation properties, PUR sandwich panels are commonly used for:

- Cold storage and cold storage facilities: To maintain low temperature environments, PUR sandwich panel is ideal.

- Residential and Commercial Buildings: Often used on exterior walls and roofs to provide good energy efficiency.

- Light industrial construction: suitable for projects that require rapid construction.

Applications of PIR Sandwich Panel

PIR sandwich panels are widely used in: due to their excellent fire resistance and thermal insulation effect:

- Industrial buildings: such as factories, warehouses, etc., especially in environments with high temperatures or high fire risks.

- Public facilities: such as schools, hospitals, etc., buildings with higher requirements for safety and fire protection.

- Cold chain logistics: In food and pharmaceutical storage, PIR provides good insulation and fire protection effects.

5. Cost comparison

Initial cost

The initial cost of PUR sandwich panel is generally lower than that of PIR sandwich panel. Due to its relatively simple production process, PUR may be more economical in material procurement and construction.

Long term cost

Although PUR sandwich panels have a lower initial investment, their poorer fire resistance can lead to higher insurance premiums and maintenance costs. Relatively speaking, PIR sandwich panels may save more money in long-term use due to their superior fire resistance, especially in environments that require frequent inspection and maintenance.

6. Conclusion

To sum up, PUR sandwich panels and PIR sandwich panels each have their own advantages and disadvantages and are suitable for different building needs. PUR is suitable for general residential and light industrial buildings due to its good thermal insulation performance and low initial cost. PIR has become the first choice for high-security buildings due to its excellent fire resistance and thermal stability.

When selecting sandwich panels, the specific needs of the project, budget, climatic conditions, and fire protection requirements should be considered. Through a comprehensive understanding of PUR and PIR sandwich panels, architectural designers and construction parties can make more reasonable material choices to ensure the safety, economy and comfort of the building.