Differences in the panel types of rock wool sandwich polyurethane edge banding board

In fact, there are many classification standards for rock wool sandwich polyurethane edge banding board. It can be classified according to the core material, thickness, or panel type. No matter how it is classified, the only purpose is to let customers and friends clearly and accurately distinguish the rock wool sandwich polyurethane edge banding board at the first time. Today we will explain one of the classification standards of wall panels-plate type.

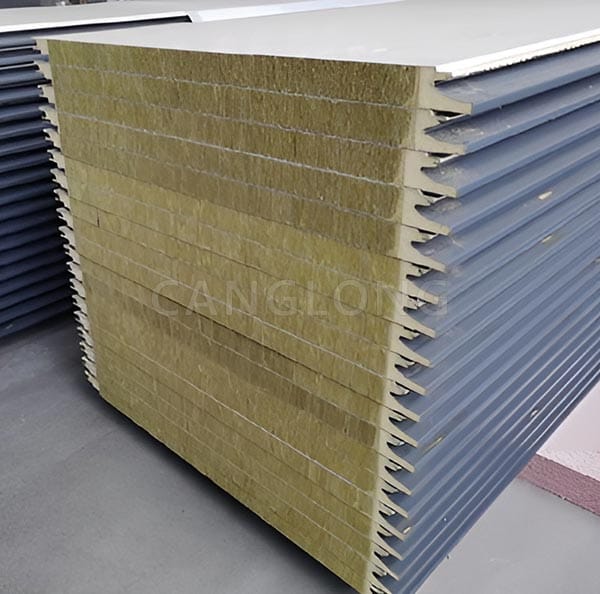

I believe that friends who have a certain understanding of rock wool sandwich polyurethane edge banding panel will definitely find that there are many textures on the surface of rock wool sandwich polyurethane edge banding board and the pressed shapes are also different. So what is the difference between these rock wool sandwich polyurethane edge banding panels?

First of all, let’s talk about the distinction of the outer surface morphology of the panel. Because different buildings have different requirements for rock wool sandwich polyurethane edge banding panels, designers who design industrial exterior walls will make a different distinction between the panels of rock wool sandwich polyurethane edge banding board according to the requirements of the relevant drawing design beauty.

First of all, we say that the smooth surface is pure flat, the literal meaning is very clear, that is, the most original state of using color steel plate, pure flat surface. This type of polyurethane edge sealing rock wool sandwich panel with an external surface is generally used on the exterior walls of large industrial parks. From the appearance, not only are all the rock wool sandwich polyurethane edge banding board self-contained, but they also blend in with the light and shadow of nature, which can be described as magnificent.

Then let’s talk about another surface form, “ripples”, which can also be called “small ripples”. This type of rock wool sandwich polyurethane edge banding panel is generally a horizontal polyurethane edge banding rock wool sandwich panel, which not only increases the board strength of the rock wool sandwich polyurethane edge banding board, but also increases the beauty of the board. Different angles and different lights will present different visual experiences when hitting the polyurethane edge sealing rock wool sandwich panel.

There are also two external surface forms that are not often seen on the exterior walls of conventional industrial buildings, embossed embossing and mini ripples on rock wool sandwich polyurethane edge banding board. These two forms are for image engineering with strict requirements on the appearance of the building.

At this point, we need to briefly introduce the users of rock wool sandwich polyurethane edge banding board. Generally, the application fields of rock wool sandwich polyurethane edge banding panels are industrial plant exterior walls, image engineering, waiting rooms, logistics centers, large supermarket systems and other steel structure exterior walls. When using polyurethane edge banding rock wool sandwich panel in these fields, the requirements for the shape of the panel are relatively strict. The outer surface shape introduced above is very popular.