How to choose high-quality PU panel products?

In the fields of building decoration, industrial manufacturing, etc., PU panel (polyurethane sandwich panel) occupies an important position and is widely used for its excellent thermal insulation, sound absorption and noise reduction, light weight and high strength. However, the quality of PU board products on the market is uneven. For consumers, how to discern and select high-quality PU sandwich panel has become a crucial issue. Next, this article will deeply analyze the methods and key points of selecting high-quality PU board products.

1. In-depth exploration of product materials

The core raw material of high-quality PU panel is polyurethane, which has a stable chemical structure and excellent performance. When purchasing, be sure to check the raw material test report of the product to confirm whether high-quality polyurethane raw materials are used. Some inferior PU sandwich panels on the market may use recycled materials or raw materials with lower purity. Such products will not only significantly reduce various performances, but are also likely to cause environmental problems. In addition, attention should also be paid to the density of the board. Under normal circumstances, PU panels with moderate density are more balanced in various performances such as thermal insulation and mechanical strength. For example, the PU board used for building insulation can ensure good insulation effect and maintain sufficient mechanical strength with appropriate density.

2. Comprehensively examine product performance

Thermal insulation performance: This is one of the most critical performances of PU sandwich panels. High-quality PU boards have low thermal conductivity and can effectively block heat transfer. Consumers can judge the thermal insulation performance of the product by referring to the thermal conductivity test data of the product. Generally speaking, the lower the value of the thermal conductivity, the better the thermal insulation performance. In actual use scenarios, PU boards with excellent thermal insulation performance can significantly reduce energy consumption, thereby saving heating and cooling costs.

Sound absorption and noise reduction performance: For places with high sound insulation requirements such as conference rooms and recording studios, sound absorption and noise reduction performance is particularly important. High-quality PU panels have a unique porous structure that can effectively absorb sound waves and reduce noise interference. The sound absorption and noise reduction capabilities can be evaluated through on-site testing or by checking relevant professional data such as sound absorption coefficients.

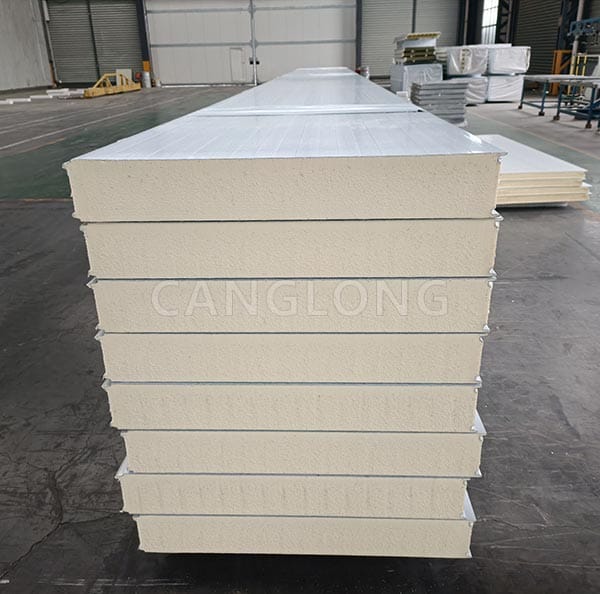

Mechanical strength and durability: High-quality PU boards should have sufficient mechanical strength and should not be easily deformed or cracked during use. When purchasing, you can carefully observe whether the surface of the board is flat and whether there are obvious defects. At the same time, you should have a deep understanding of the service life and weather resistance of the product to ensure that it can function stably and for a long time under different environmental conditions.

3. Carefully check the appearance quality

Surface flatness: The surface of a high-quality PU panel should be smooth and flat, without defects such as unevenness, bubbles, and cracks. Touch the surface of the board with your hand to feel its texture. If it feels rough or granular, it is likely that there is a problem with the production process.

Color uniformity: PU sandwich panels with uniform color indicate that the raw materials are mixed very evenly during the production process, and the product quality is more trustworthy. On the contrary, if the color of the board surface is different in depth, then the product is likely to have quality risks.

4. Focus on brand and reputation

Choosing PU sandwich panel products from well-known brands often provides more reliable quality assurance and perfect after-sales service. Well-known brands usually pay great attention to product quality and brand image, and strictly control the quality of every link in the production process. At the same time, consumers can also use the Internet, industry forums and other channels to understand other users’ evaluation of the product and actual use experience, so as to understand the advantages and disadvantages of the product more comprehensively and deeply.

5. Rational comparison of prices

Although price is not the only criterion for measuring product quality, PU panels with too low prices often have product quality problems. When purchasing, consumers should not only covet temporary cheapness, but should comprehensively consider factors such as product performance, quality and price, and choose products with high cost performance. This can not only ensure that the product meets actual needs, but also achieve effective cost control.

In summary, the selection of high-quality PU panel products requires comprehensive consideration from multiple dimensions such as material, performance, appearance, brand and price. Only in this way can we accurately select high-quality PU sandwich panels that meet our needs, and provide solid guarantees for the smooth development and long-term stable operation of engineering projects. Before purchasing, it is recommended that consumers do more market research and consult more professionals in the industry to avoid unnecessary losses due to improper selection.