The difference between PUR and PIR polyurethane cold storage panel

Polyurethane sandwich panels have increased demand in the industrial system, especially for cold storage projects. PUR and PIR are two chemical composition structures of polyurethane hard bubbles, which are widely used. The main difference between them is fire resistance, thermal insulation performance, capacity, temperature range and water absorption rate. The PUR foam is generally used in B3, with high thermal conductivity, light capacity, a wide range of temperature resistance, and high water absorption. The PIR bubble is generally B2, with lower thermal conductivity, slightly heavier, wider temperature resistance, and low water absorption rate.

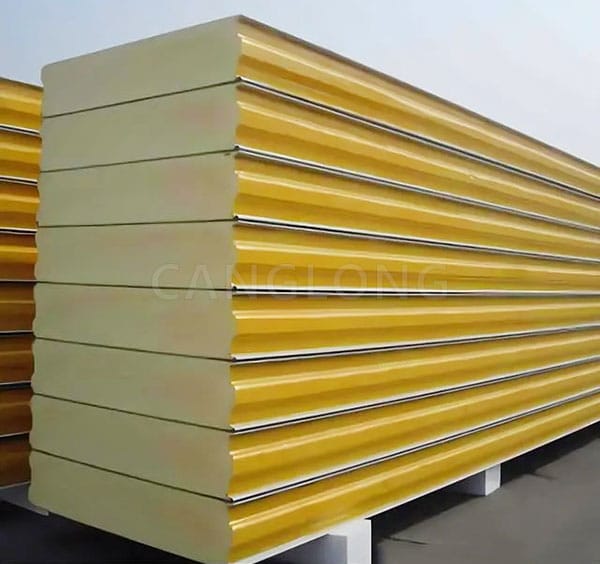

There are more and more demand for polyurethane sandwich panels in today’s industrial system. When it is used in the cold storage project, it has excellent thermal insulation effects, so how is PIR and PUR polyurethane cold storage panels distinguished and where the differences are.

PUR and PIR refer to the composition of the chemical composition of polyurethane hard bubbles. Both PUR and PIR can be compounded as the core material and various rigid or flexible materials as facial materials.

PIR’s full name Polyisocyanurate Foam, called “polythexyl acid lipic lipid”, PIR is made of foaming materials by reaction with polyether after a touch media. It is an ideal organic low temperature insulation material. It has small thermal conductivity, light shock -proof, and strong adaptability. Widely used in thermal insulation and insulation of oil refinery, chemical factories, ethylene, fertilizer, cold storage and construction industry.

PUR full name Polyurethan, is a polymer with a repeated structural unit with amino ampamate chain segments composed of isocyanate and polyol. Essence PUR products are divided into two categories: foam products and non -foam products. Foam products include soft, hard, and semi -hard PUR foam plastic; non -foam products include coatings, adhesives, synthetic leather, elastic body and body Elastic fiber, etc.

The difference between PUR and PIR

1. The difference between fire resistance:

- PUR foam: Generally, B3 levels can be reached level B1 or B2 by adding flame retardants.

- PIR foam: Generally, B2 levels are generally reached B1 by adjusting the concentration of polychenyl acid ester rings and other formula technology to reach B1.

2. The difference between insulation performance:

- PUR foam: Thermal conductivity is generally 0.022W/mk-0.026W/mk (25 ° C).

- PIR bubble: The heating coefficient can be as low as 0.019W/mk (25 ° C).

3. Differential difference:

- PUR foam: Generally, 38-40 kg/m³ can meet the more satisfactory strength requirements.

- PIR foam: Generally, 40-45 kg/ m³ can be achieved to meet the more satisfactory strength requirements.

4. The difference in temperature resistance range:

- PUR foam: General -185 ℃ ~+110 ℃.

- PIR bubble: It can reach -196 ℃ ~+205 ℃.

- PUR clip core plate: Generally use it for a long time below+85 ℃.

- PIR clip cores (INDEX index above 250 or more) are generally used for long -term use below 150 ° C.

5. The difference between water absorption rate:

- PUR bubble: generally 2.5% ~ 3%.

- PIR bubble: can reach 0.9%.