Which insulation sandwich panel is more suitable for cold room, PIR or PUF?

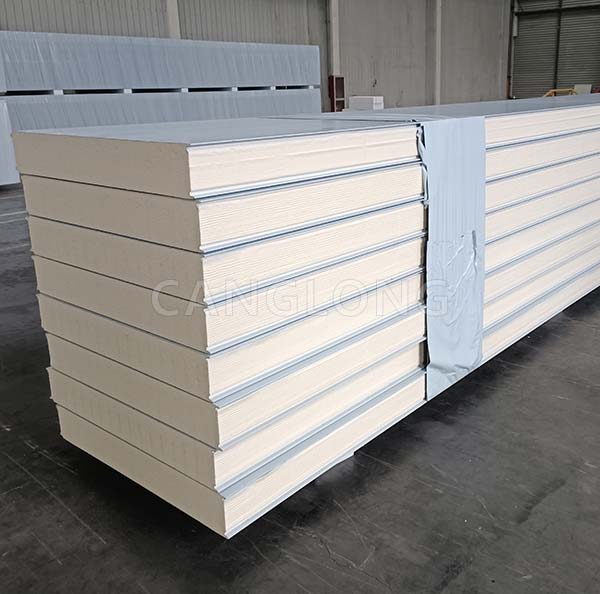

In the construction of cold room, insulation sandwich panel is the core material for maintaining low temperature environment, and its performance directly affects energy consumption and operating costs. At present, the mainstream choices in the market are PIR panel (polyisocyanurate) and PUF panel (polyurethane), which differ in structure, performance and application scenarios.

1. Structural composition comparison

PIR panel: with polyisocyanurate as the core material, galvanized steel plate or color steel plate is coated inside and outside, and formed by high-pressure foaming. The molecular structure of the core material is more stable and has strong high temperature resistance.

PUF panel: The core material is polyurethane foam, and the metal panel composite process is also used, but the foaming density is slightly lower, and the cost is more advantageous.

2. Performance characteristics and advantages and disadvantages analysis

PIR Insulation Sandwich Panel

Advantages:

- Excellent thermal insulation performance: low thermal conductivity (0.022~0.028 W/m·K), thermal insulation effect is about 10%~15% higher than PUF panel, more suitable for ultra-low temperature cold storage room.

- High fire resistance: up to B1 flame retardant, carbonization without dripping when encountering fire, safer.

- Strong corrosion resistance: anti-moisture penetration, not easy to deform after long-term use.

Disadvantages:

- High cost, about 20%~30% higher than PUF insulation sandwich panel price.

- The production process is complicated and the customization cycle is long.

PUF Insulation Sandwich Panel

Advantages:

- Economical: low unit price, suitable for projects with limited budget.

- Lightweight and easy to install: low density (30~50kg/m³), convenient construction.

Disadvantages:

- Weak fire resistance (usually B2 level), harmful gases may be released at high temperature.

- After long-term use, the thermal insulation property decays quickly and requires regular maintenance.

3. Recommended applicable scenarios

PIR Insulation Sandwich Panels:

- Applicable to cold storage, pharmaceutical cold storage, cold chain logistics center and other scenarios with long-term low temperature (below -25℃).

- Projects with high requirements for fire protection and environmental protection (such as food processing plants).

PUF Insulation Sandwich Panels:

- Suitable for small and medium-sized cold rooms (0℃~-18℃) for short-term storage and transportation, such as supermarket cold fresh areas and temporary storage.

- Ordinary industrial scenarios with limited budget and no strict fire protection requirements.

4. Conclusion and selection recommendations

If you pursue long-term thermal insulation and safety compliance, PIR panel is the best choice for cold room. If you focus on cost control and fast construction, PUF panel is more cost-effective. It is recommended to make a comprehensive decision based on project budget, temperature control requirements and operation and maintenance cycle, and give priority to thermal insulation sandwich panel suppliers with fire protection certification to ensure material quality and after-sales service.